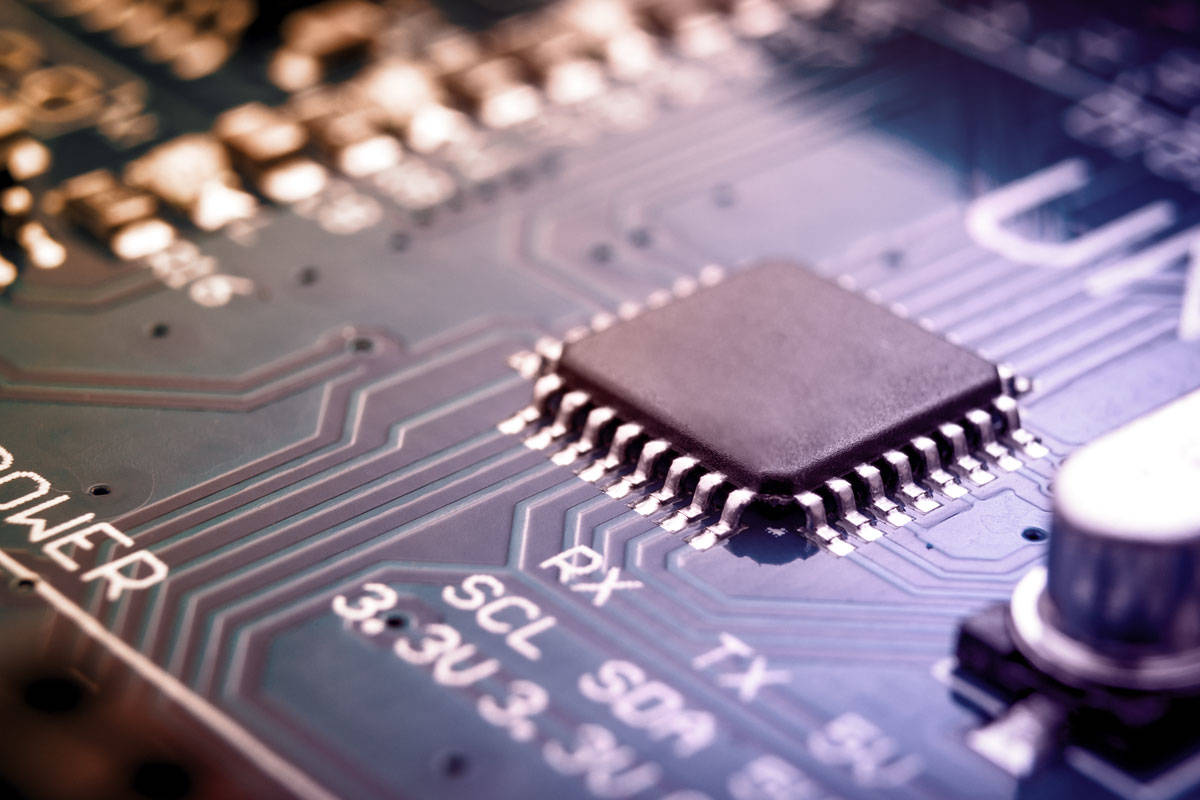

Semi-Conductor Industry

A semi-conductor is a crystalline or amorphous substance that can conduct electricity under certain conditions. Devices made of semi-conductors - notably silicon - are essential components of most electronic circuits.

The conductivity of a semi-conductor is between that of an insulator and that of most metals - generally due to the addition of an impurity or due to temperature effects. This addition of an impurity is known as doping. The method in which a a crystal is doped allows for control in the way it carries an electrical current.

This is a high tech industry with manufacturing mainly in clean rooms. Semi-conductor chemistry is mainly based around chemical treatments by solvents for degreasing components and the shrinkage of residual resins using chemicals sucah as iso-Propanol, Trichloroethylene, Acetone and other alcohols; or acid/base reaction chemistry. Alkalis are used to oxidise the the semiconductor, acids are used to remove oxides. Typical chemicals used include Hydrogen Peroxide, Ammonium Hydroxide, Sodium Hydroxide, Sulphuric Acid, Nitric Acid, Orthophosphoric Acid, Hydrochloric Acid and Hydrofluoric Acid.

Mixtures of Nitric Acid and Hydrofluoric Acid are often used to engrave silica and Hydrofluoric Acid is often used due to its ability to dissolve oxides. Particular care must be taken with Hydrofluoric Acid due to the corrosive and toxic risks. Please see our pages on Hexafluorine® and our download on Hydrofluoric Acid.

Semi-conductor production areas usually utilise these chemicals in closed lines with little risk from chemical splash but storage, decanting and maintenance programs all carry their own risk as do quality testing processes.

Additional Reading: