Testimonials

Chemical Safety - Anticipate accidents and prevent harm

This is our ethos and we are always grateful when clients share their experiences with us, of how we have assisted them to achieve this.

Original documents of all testimonies are available on request.

A colleague was working with Sulphuric Acid in our laboratory when an unfortunate accident occurred which resulted in multiple splashes of acid on the skin of the arms and the wrist. Fortunately we have stocked our laboratory with a Diphoterine® Wall Mounted Station so we were able to initiate treatment with the Mini-Dap spray immediately. Use of Diphoterine® significantly improved the outcome and prevented serious, long term damage to the skin. I sincerely recommend that any laboratory thats uses acids/bases has a Diphoterine® kit available for immediate use should an accident occur. May 2023

Health and Safety Manager - Biopharmaceutical Company

A couple of drops of dilute Sulphuric Acid fell onto the back of an employees hand. As a precaution, Diphoterine® solution was applied to the affected area. Slight reddening was observed initially but this quickly went away and no further symptoms were observed. As a company, we are happy to have this precautionary solution on hand and all of our staff have been trained in its use.

Health and Safety Manager - Manufacturer

We have no doubt that this full recovery is due to the use of Diphoterine® early on in the incident, we would highly recommend it’s use. This is the feedback received from a client following an on-site incident. Two production operatives were making final preparations to transfer a quantity of 25% Caustic solution from one vessel to another. One of the last preparations was to open a manual valve, as it was opened the jointing material failed, spraying a small quantity of caustic solution into the face of one of the operators. Eye protection did reduce the volume of caustic solution entering the eye.

Compliance Technician - Speciality Chemical Manufacturer

A member of the maintenance team whilst affecting repairs/maintenance on a process tank containing 18% Sulphuric Acid slipped plunging their naked arm up to their elbow into the solution. The use of the Diphoterine® MiniDap reduced the potential harm to the point that we actually questioned whether Sulphuric Acid was in the tank as there was not a blemish on the individual. Having a variety of potentially hazardous chemicals being processed at site led us to invest heavily in the DipHex suite of first aid solutions and you are never sure if you have made the right decision until you have to use them. Mind is now resting easy that should the worst happen we can react with a minimum of impact to our employees health

Surface Engineering / Aerospace Industry - Health and Safety Manager

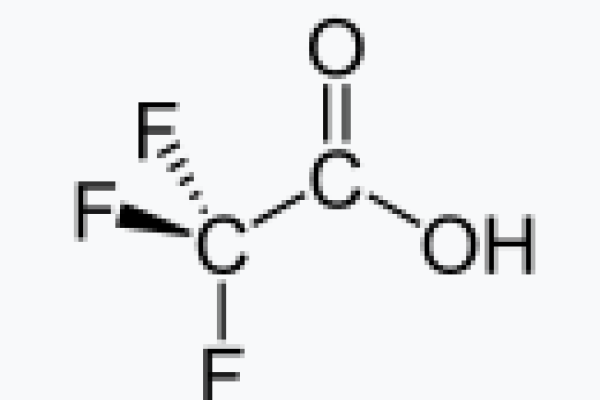

A scientist was splashed with Trifluoroacetic Acid (neat) whilst setting up a routine reaction. The neck and collarbone were affected. Diphoterine® spray was applied to the area 2-3 minutes following the splash. Due to the delay in commencing the decontamination a second canister of Diphoterine® was used - following the correct delayed wash protocol. No further medical treatment was required, small blisters initially seen faded overnight, the area healed quickly leaving no scarring. The manager of the laboratory states "we are very happy with the efficacy of Diphoterine®"

Anonymous - Scottish Scientific Laboratory

Diphoterine® has been on site since early 2000. The reason for introducing it was following an incident where an engineer was carrying out maintenance on the processing plant and, despite wearing safety glasses, a flake of dried caustic fell off an overhead pipe and entered his eye. Traditional water washing was carried out and the engineer was transferred to hospital. Fortunately he did not lose his sight but the injury was sufficient to warrant an improved protocol for such a situation. We have been fortunate not to have had any further serious injuries from chemical burns at Worthing, however we have had cause to use Diphoterine® for some minor incidents. A recent example of this is where a technician in a laboratory was using a Pasteur pipette with 70% Nitric Acid and dripped some onto the sleeve of her lab coat. She didn't notice until she felt the acid on her arm. With the help of a colleague he quickly removed the coat and sprayed her arm with a 200ml DAP spray. I saw her arm an hour or two later and there was barely a mark on it. She required no medical treatment, other than being checked by a first aider and she was able to continue as before.

GlaxoSmithKline - Jan Keith Environmental Health and Safety Advisor

Although we do not use chemicals of any kind in our process operation we do have a Maintenance department where chemicals are used and we must keep our facility (where we make safety critical items) clean at all times, again chemicals are used. To this end , we at Peterlee, are using Diphoterine® in case of emergency for three years. In June 1999 we had occasion to use it for the first time. This incident involved a cleaning technicican who was splashed in her eye whilst emptying a cleaning liquid from a 5l drum into a spray bottle. This gel was undiluted with a pH value > 8.2. The treatment involved Diphoterine® Eyewash which gave relief and only one application was required. The technician completed her shift and has had no further problems. I recommend the use of Diphoterine® to all users of chemicals. I stock it in all of our First Aid locations on site and have trained all First Aiders in its application.

TRW Automotive - R L Hann Safety Co-ordinator

Diphoterine® was introduced at the Lonza Slough UK sites in 2002 because we use corrosive, acid and irritant products on a daily basis. Whilst Lonza prides itself on developing safe processes and Lonza personnel have a huge respect for chemicals and the potential hazards when handling them, accidents can still happen, equipment can fail or storage containment can be breached resulting in the unexpected release of a hazardous substance. Lonza personnel have used Diphoterine® over the last 10 years as a first aid response when their skin or eyes have come into contact with a chemical. This has meant since the introduction of Diphoterine® no member of staff working for Lonza has been left with any lasting effects from chemical contact - an amazing result.

Lonza Biologics - Paul McCarroll EHS Specialist